Dairy and meat are two common sources of foodborne illness in the U.S.

Because of this, producers use methods to test food for bacterial contamination before making it available to the public. However, these methods are time-consuming, expensive, and require expert training to perform.

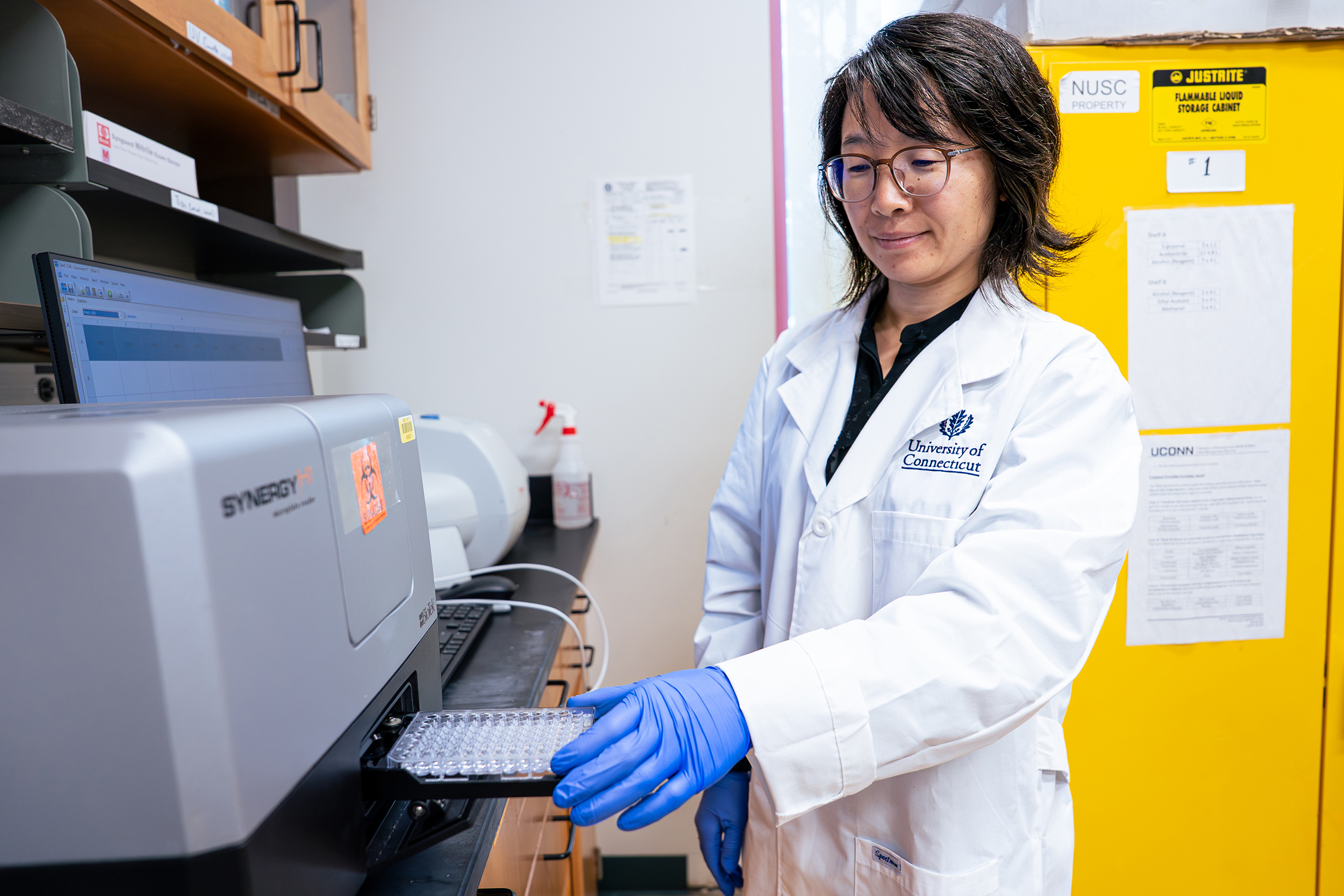

Researchers Zhenlei Xiao and Yangchao Luo in the Department of Nutritional Sciences have developed new methods powered by machine learning to test for bacterial contamination and spoilage that radically reduce the cost and time required to perform them.

Their method works by using a 96-well plate — a plate with many small wells to fill with samples — paired with an array of 12 sensors.

The sensors react differently to different species of bacteria based on their molecular structure. These interactions produce unique patterns. By feeding these patterns into a machine learning algorithm, the researchers trained the computer to detect the pathogens and spoilage bacteria based on the patterns.

“We hope to develop a technology that can simultaneously detect as many species as possible so that we can easily trace back the original source of contamination,” Luo says.

So far, this new technology can detect eight different pathogenic and spoilage bacteria in milk in just two hours with more than 98% accuracy. An app that enables a smartphone to read the data the sensors produce is currently under development.

The research team is also developing a sensor to detect volatile organic compounds (VOCs), which are produced by bacteria that cause spoilage in meat. These sensors can detect VOCs to determine the lipid oxidation status in food products, like ground beef, for example, and therefore indicate their freshness and predict their shelf life.